What are the Advantages of using Roll Formed Custom Profiles in Assemblies?

Markus H.'s head is spinning. For the first time, the ambitious young engineer has been given full responsibility for the design of a module for a new production plant. He’s already come up with some good solutions, but there’s still a big question mark hanging over the process. He knows that every single assembly is relevant to the smooth functioning of the whole system. There’s no room for error: every piece has to perfectly fit with the next. Ultimately, it’s a question of assembling a large number of highly complex components with different subsystems into a functional end product.

A functioning assembly is the bare minimum - that goes without saying. But Markus wants to make something that will knock the boss off his feet. For that, Markus has to deliver more than the base-line requirements: he needs to incorporate efficiency across the board, low costs, and minimal use of resources. That’s what will make his design a real success. At the last EuroBlech technology fair, he overheard something about roll-formed custom profiles. Maybe that's his solution. But what exactly can these custom profiles do?

10 good Reasons to use Roll-Formed Custom Profiles: Less Complexity, more Efficiency

Roll-Formed Custom Profiles are superior to off-the-shelf products in many ways. If Markus H. looked into the topic a little more closely, he’d quickly find 10 strong arguments for choosing this bespoke solution:

Reason 1: Optimization of Component Requirements

Assemblies typically require a combination of different processes and techniques to connect multiple off the shelf components to get the shape you need. Roll forming works by integrating various processing methods directly into the production process, creating the final desired shape without the added, separate steps. In this way, roll-formed custom profiles can save time and money as well as increase the accuracy of the end product.

Reason 2: Minimizing technical Risks

Roll-formed custom profiles can be manufactured with much tighter tolerances since individual components within the assembly no longer have to be separately connected with each other to create the final shape: it’s all done together in a combined process. This in turn results in the reduction of technical risks.

Reason 3: Reduction of Procurement Processes and Logistics Expenses

By having fewer required components, the procurement process can be reduced, and with it also comes the advantage of using less material. Accordingly, the associated logistics processes will also conveniently be optimized at the same time.

Reason 4: Less Documentation

Reducing the number of components also has the added bonus of reducing the effort required in documentation. This leaner process will involve fewer technical drawings, fewer records for standard references and less packaging expenses.

Reason 5: Further Reduction of additional Parts

If fastening points can be created without the use of additional parts, this results in a knock-on effect in the number of components required overall: numerous connecting parts that were previously linked to the additional parts needed for fastening points can be done away with.

Reason 6: Less Outsourcing

If, for example, the material needs to be refined to protect it from environmental influences, all that is needed for the roll-formed custom profile from a single source is coordination with the roll profiler directly - no additional 3rd party needs to be brought into the process.

Reason 7: Shorter Processing Times

Custom profiles can usually be mounted directly, which significantly reduces the complexity of process steps and procedures. The result is shorter processing and throughput times for the user.

Reason 8: Less Space required

Roll-formed custom profiles deliver optimal results, even in tight spaces. No other comparable method can accommodate so many different functions in limited spaces and in tight installation situations.

Reason 9: Longer Service Life

The right combination of custom profile and material allows for a variety of highly sustainable solutions. In this way, the service life of a product can be improved both by direct means, e.g. by using higher quality steel grades, and indirectly, e.g. by protecting a weld seam from corrosion during the roll forming process.

Reason 10: Better Overview

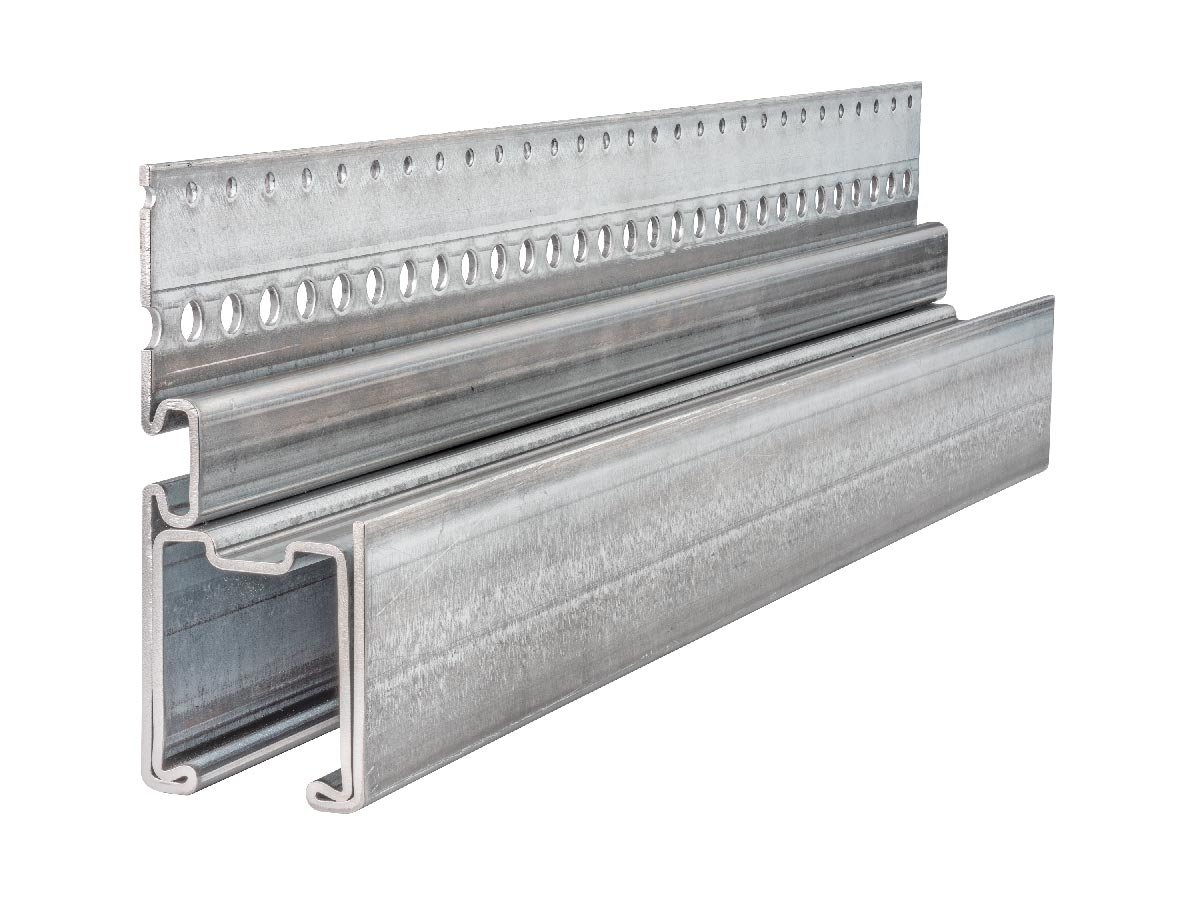

The effect of custom profile solutions can be illustrated using this relatively simple example:

The illustration shows a symmetrical assembly, on the right, in the form of a one-piece custom profile solution, and on the left as a two-piece assembly with a welding process. The production of the two piece variant requires significantly more effort. It needs its own infrastructure in the form of a machine welding line and the associated investments, employee know-how, precautions to comply with safety requirements and equipment.

All of this effort could be noticeably reduced with a one-piece custom profile solution. And as a bonus, the possibility of integrating additional functions with this variant opens up further opportunities for the manufacture of innovative, more complex products.

And here's a little treat for fans of more complex profiles ;)

Conclusion: Custom Profiles - Combining the Best of all Worlds

Roll-formed custom profiles offer an unbeatable combination of modern materials, manufacturing processes, and product characteristics. They combine the best of all worlds by enabling the manufacture of bespoke solutions to fit individual requirements, using the most suitable material. What’s more, roll-formed custom profiles reduce the complexity in the manufacturing process, ensuring maximum efficiency.

Where other processes require, for example, coordinating three interface partners - all that is needed is the roll profiler. Where otherwise you might need three or more off the shelf standard shapes to be combined to create your desired profile, now you only need one product: the custom roll formed profile. And whereas you’d need documentation and packaging for three parts with another solution, with roll forming you only need it for one. This saves time, nerves and money - not only for our ambitious engineer Markus H. and his boss…but for you, too!

Let’s work together to create your Perfect Profile

Make your life easier, and your products even better. When you come to us, you don't even need a completed concept for your custom-made custom profile. The basic idea is enough: we’ll work together to find the ideal solution for you.

Read more

Similar articles

Welser Creator: Uses, Advantages, & Expert Tips

What’s really possible with Welded Custom Profiles?