What’s really possible with Welded Custom Profiles?

Welded custom profiles play a key role in numerous branches of industry: it’s hard to imagine the construction or car manufacturing industries without them. And it makes sense. Roll forming opens up a wide range of possibilities for the realization of construction designs in a resource-saving and efficient manner. While many designers and product developers have an understanding of the merits of different manufacturing materials, often they don't know what professional roll formers are really capable of. Their full potential is only revealed when considering those aspects that are usually less prominent, such as the choice of material or integrated downstream processes. With that in mind, we’d like to use this article to show you what welded custom profiles can really do.

What exactly is a Welded Custom Profile?

Both open and closed profiles are produced on roll profiling machines. In addition to roll forming, closed profiles also require a joining process: in most cases this consists of a welding process directly integrated into the production flow. The roll formed metal strip is brought together and welded closed to form the finished component.

When it comes to steel, most product developers and designers now probably think of structural steel, and not without reason. In fact, no other material is used more frequently in the manufacture of welded custom profiles. In areas with more specific requirements, however, alternatives are in demand.

Materials under the Magnifying Glass: 3 Alternatives to Structural Steel

In principle, any material that can be formed and welded is suitable for the production of welded custom profiles. In addition to the classic structural steel, we work with the following 3 material groups in roll forming:

- Stainless Steel

As a production material, stainless steel is not only relatively expensive to purchase, but also brings up processing costs due to the greater effort involved. The material properties of stainless steel offer nearly complete protection against corrosion. Accordingly, the production of a profile does not require any subsequent processing steps when it comes to the best possible protection against environmental influences, such as sea salt or high humidity.

In addition to the production of railway cars, typical areas of application include coastal construction projects. Stainless steel also meets the highest hygiene requirements, making it widely used in medicine and in the food industry. - Pre-galvanised Steel

Pre-galvanised steel, like structural steel, is relatively inexpensive. However, various processing steps destroy the protective zinc layer on the cut and punched edges. To restore the corrosion resistance, the weld seam needs to be re-galvanised.

Profiles made of strip-galvanized steel are generally used where good corrosion protection is required at a relatively low cost. They’re often used in substructures for Photovoltaic (PV) systems, as well as in storage and conveyor technology, or in the construction industry in the form of shuttering or ceiling protection profiles. - Aluminium Alloys

Similar to steel, aluminum is also characterized by a large variety of materials. There are currently around 200 different aluminum alloys, some of which differ greatly in properties such as formability, strength or weldability. Aluminum alloys are an option when components need to be lightweight and corrosion resistant.

A specific area of application is, for example, vehicle construction, where they are installed in the form of welded aluminum profiles. But, especially when it comes to material for welded custom profiles, there are often better alternatives to the comparatively expensive aluminum alloys in the world of steel.

As we’ve seen, not all materials are created equal when it comes to covering specific requirements. Choosing the right material is just one of the challenges on the road to the right product. Especially when it’s so complex that a profile alone is no longer enough.

Welding Multiple Profiles into Assemblies

The aim of roll forming is to incorporate all the required functions into a one-piece profile in a single step. However, some cross-sectional shapes, e.g. mounting rails are so complex that they can only be realized by welding several profiles together to form so-called assemblies. This is especially true when:

- the final product is too large for a one-piece profile.

- not all required functions can be accommodated in one profile.

- different material grades and material thicknesses can be combined.

If a product can be implemented both as a one-piece custom profile and in the form of an assembly, the client usually opts for the first variant, because this can be realized much more cost-effectively compared to the multi-part alternative. The few exceptions result from the need for highly functional products in small quantities, such as fire brigade ladders requiring the lowest possible weight.

Assembly Production at Welser Profile

Based on our many years of experience, we have perfected our profiling systems through in-house development while continuously optimizing our processing methods. For example, Welser Profile is one of the very few roll formers that also offers laser beam welding. This welding method is characterized by extremely low heat generation, enabling the starting material to be processed without changing its inherent properties.

The more complex the requirements, the more we’re in our element. We not only have the most modern equipment, but also years of project experience in the production of ultra-complex assemblies under our belt. These include cross-sections for:

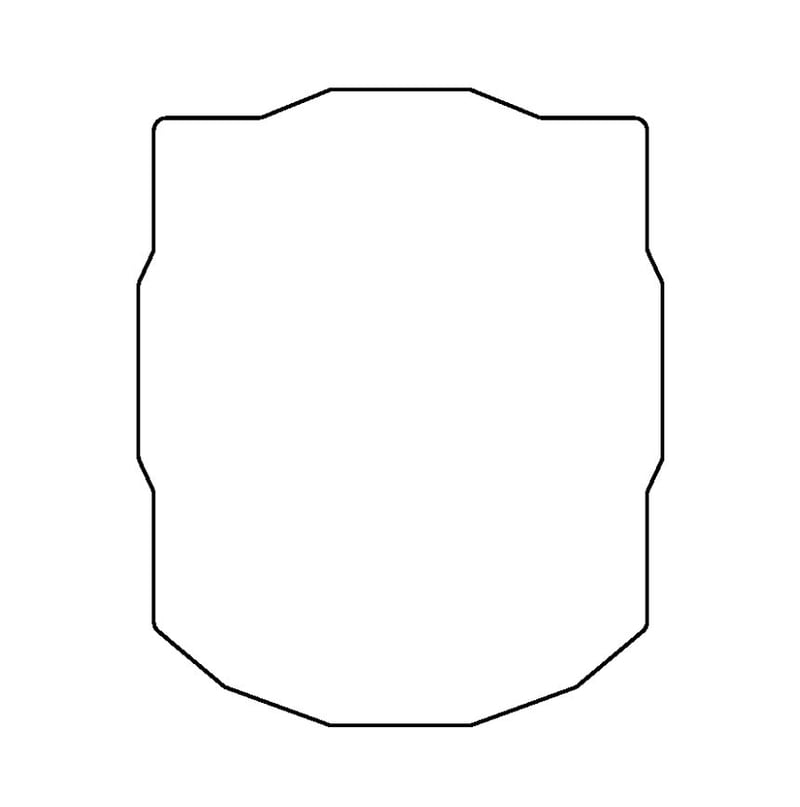

- Thin-walled profiles with the highest tensile strength in very large dimensions, e.g. crane booms used for facade repairs.

Module Cross-Section: Very large, high-strength and thin-walled

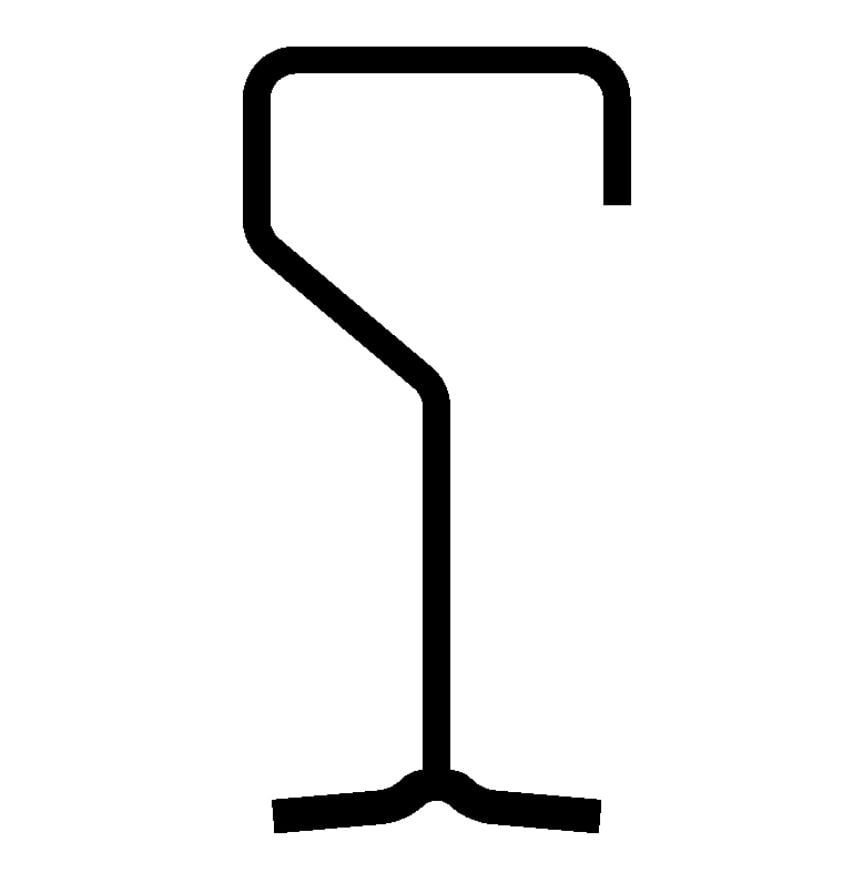

- Assemblies made of stainless Steel, e.g .in the hygiene area or overhead conveyors in poultry factories.

Assembly Cross-Section: stainless steel, hygienic areas

Assembly Cross-Section: stainless steel, hygienic areas -

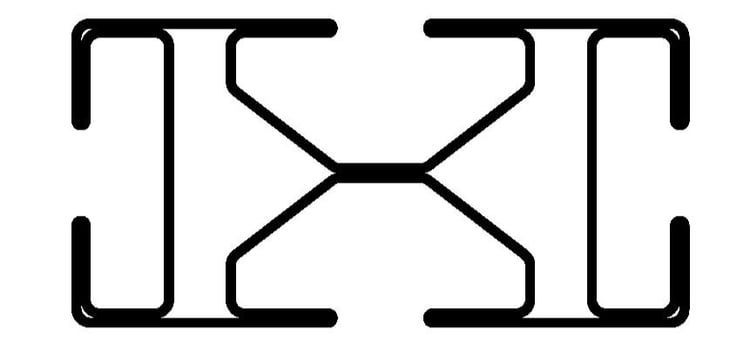

Complex geometry, e.g. to increase the moment of resistance or to integrate as many functions as possible.

Assembly Cross Section: Complex geometric shape

Conclusion: Innovative Solutions for Complex Requirements

With the right machines and processes, as well as the necessary know-how, a good roll former can produce complex assemblies that go far beyond the possibilities of conventional profiles. So if you aren’t sure whether your component can be implemented with the desired functions, just come to us. Together we’ll find a way. You define the requirement, we’ll develop the right solution.

Read more

Similar articles

High Quality Custom Profiles for Cabin Construction

What are the Advantages of using Roll Formed Custom Profiles in Assemblies?