5 Innovation Topics you should definitely consider in Mechanical Engineering in 2024

Innovation has become a bit of an overused buzzword. Just because something is new doesn’t necessarily make it innovative. A quick glance at Wikipedia can give you an idea of the difference between Invention (a new concept), and Innovation (a product or service that has been successfully implemented and applied in the current market). Book printer Friedrich Koenig’s innovative, high-speed, steam powered press was introduced widely onto the market in the early 19th century, replacing strenuous and costly manual printing. He wasn’t the first - some of his predecessors invented printing machines that were increasingly made of steel instead of wood, but their inventions were only used sporadically. Thanks to Koenig's innovation, newspapers and books suddenly became suitable for the masses.

The pressure to innovate and the intensity of innovation - 6.1% in Germany in 2021 according to a Statista survey - are particularly high in mechanical engineering. This is felt not least by product developers, from whose heads more rather than fewer ideas with high future potential should bubble up.

The following 5 innovation topics will keep us busy in mechanical engineering in the future:

1. Durability

Who hasn’t heard their grandmother talking about the old days when a washing machine was a lifetime purchase that didn't have to be replaced every 5-6 years like these newfangled, modern contraptions? Well, the lifespan of consumer products may have become less important, but product longevity still plays an essential role in industry. Risk assessments and budgetings for future expenditures are made on the basis of the durability, i.e. the period in which systems and machines are fully operational.

The Challenges of durable Machines and Components:

- Cheap Components:

In our globally networked world, you’ll be able to find more and more producers with cheaper and cheaper options - and the temptation to go that way increases along with your budget pressure. Unfortunately, cheap steel engineering components will rarely have the durability you’re looking for to give your machines their desired longevity and can end up costing you more in the long run. - Short Term Product Development:

“Innovate, but do it fast!” Product developers have to manage this balancing act time and again - the desired time to market keeps getting shorter as competitive pressure increases in the current climate. There’s hardly any time left for long-term developments and in-depth research into the numerous possibilities (of steel as a processing material, for example.) - Missing Background Knowledge:

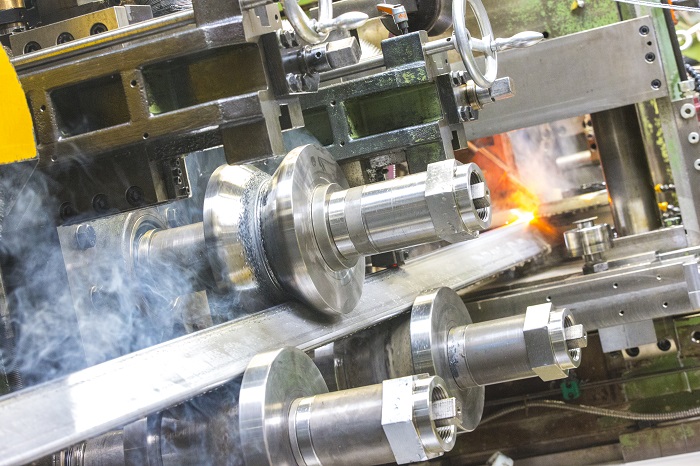

Friedrich Koenig, the innovator of the high-speed printing press, would probably never have been able to develop his innovative machine if he hadn’t continued his extensive education at university after completing his training as a master printer. In addition to general know-how, knowledge of the specific technological requirements is also important. Roll forming technology is a prerequisite for sustainable components, but most mechanical engineers learn little to nothing about this technology during their studies.

Solutions for durable Machines and Components:

- Pay Attention to Quality:

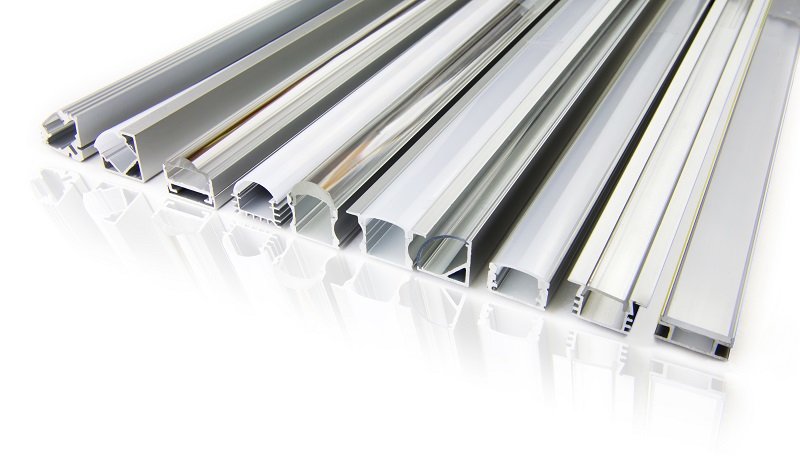

If you buy a high-end car you can be pretty sure that after 100,000 km it will still run smoothly without the engine rattling or the tail-pipe falling off on the highway. The same applies to systems and machines: load-optimized customized metal sections with precise process technology involving the laser welding of steel will last longer and work better than standard products that require compromises. - Use The Right Material for the Job:

All materials have a certain quality standard, and consequently they behave differently during processing. Product developers have to make precise selections to ensure process excellence. The material from the center of the steel coil, for example, is of a very high quality and is therefore an ideal material for custom profiles with high durability. - Collaborate on Product Development:

The more knowledge, competence and experience you’ve got flowing into product development, the higher the potential for successful, innovative developments. A team of versatile specialists is more likely to find tailor-made solutions for long-lasting products than individual developers working alone. You might have someone who excels in determining cost efficiency and another who can find the right feasibility study - together they will give you the whole picture.

2. Digitalization

It seems everyone is crying out for digitalization and digital transformation right now. McKinsey estimates the IoT in the manufacturing sector alone has a total potential economic impact of $3.7 trillion a year by 2025. The degree of digitalization in the product development process is also increasing, especially with technically required 3D simulations.

Challenges of Digitalization in Mechanical Engineering

- Interface problems:

The digital age can be a curse and a blessing, especially when it comes to working with internal and external employees. Collaboration tools accelerate cross-border exchange, but the lack of interface options can also lead to data loss and wasted time working on outdated file versions. - Initial Technical Overload:

Every newly introduced digital solution can lead to an initial overload for the users: they will need onboarding and possibly further training. And this, of course, means an investment of time and money - and you can’t be sure beforehand if this investment will finally pay off.

Solutions for Digitalization Projects in Mechanical Engineering

- Use Digital Communication Profitably:

Partnership-based exchange on equal terms puts your value-adding relationships in the foreground. This means that a customer can withdraw at any time if it turns out that the solution being offered is not 100% optimal. Digital communication is ideal for facilitating this: for example when a designer contacts his processing partner, and together they find out that there is a better alternative for product manufacture. - Use Digital Solutions from Partners:

By working with a partner, companies not only gain access to their services and expertise, but also their digital solutions. At Welser Profile, product developers can access the Welser Creator free of charge. In addition, they benefit from their cooperation through the use of profile-specific simulation tools such as Copra and 3D CAD programs such as Creo. - Keep Up with Digital Innovations:

The more product developers know about existing technologies and manufacturing methods, the more optimal solutions they will find. In mechanical engineering, for example, the possibilities of roll forming technology are not widely known, and consequently a digital novelty such as the profile as a sensor is only just on the way to becoming an innovation. Conductor tracks are integrated directly into the profile, connecting the mechanical and electronic worlds.

3. Sustainability

Sustainability is a very broad term. In mechanical engineering it refers to, among other things: systems and machines are less prone to failure, can be updated, networked, environmentally friendly, cost-efficient, and self-cleaning.

Challenges of Sustainable Products

- Long-Term Costs and Resources:

The debate about whether or not electric cars are sustainable shows the complexity of the issue in the area of tension between short-term and long-term costs and resources. Here, product developers are noticeably challenged by differing outlooks and influencing factors, and ultimately, a still somewhat opaque window looking further into the future. - Tight Budgets:

Although the public calls for sustainability are coming through more loudly every day, low budgets can make the development of sustainable products in mechanical and plant engineering difficult. With roll forming, for example, the step to your own metal section is only correspondingly small thanks to the diversity of the processing manufacturer.

Solutions for sustainable Product Development

- Think About Secondary Uses:

Secondary uses are an increasingly important innovation topic in mechanical engineering. For example: seat rails can be used a second time in the next generation of vehicles. Thanks to this double life cycle, a sustainable product development process is possible in the long term. - Strive For Sustainable Use of Raw Materials:

Solutions for the sustainable use of raw material are likely already available for many of your requirements. One example: anywhere in the world, material steel is 100% recyclable after machine use. - Find Green Partners:

Sustainable designs are developed not only by individuals, but in cooperation with all stakeholders involved. Green companies usually also convey this idea of sustainability to the outside world.

4. Simplification & Reduction

Can you turn 10 parts into just 3 to improve efficiency and reduce costs? Finding ways to significantly simplify & reduce machines and their components is one of the most important innovation topics in mechanical engineering: it promises lighter, more sustainable and more cost-effective product developments.

Challenges:

- Documentation:

Reducing the individual components of an existing product usually means a high level of documentation effort for product developers. Replacing and modifying already existing and sometimes extensive parts lists can end up being a fair amount of work. At the same time, the simplification of individual workpieces sometimes leads to an unanticipated series of additional optimizations becoming necessary. - Obligation to Provide Evidence:

"If it ain’t broke, don’t fix it." If the benefit of simplification is not immediately evident, machine builders can face an uphill battle when trying to simplify existing, functioning machines. Time and again, they have to prove that the new, simplified design actually has innovation potential and, for example, saves costs, or is particularly environmentally friendly.

Solutions:

- Get To Know New Materials and Technologies :

With your existing, running system, you already know that the materials and technologies used were what seemed optimal at the time of implementation. Now the task is to find new simplified solutions, and that requires a broad knowledge of the latest developments and products on the market. - Integrate External Expertise:

The best way for product developers to fill in gaps in knowledge, know-how and expertise is by bringing in experienced specialists and partners. These partners, in the best case scenario, are brought on board at an early stage. In this way, not only can machine components be reduced, but potential resource and cost savings can also be fully exploited from the start. - Trust Yourself:

It's always easier said than done, but innovation can only come from a place of courage and confidence. Developing something new or simplifying something that already exists is sometimes going to work, and sometimes it won’t. But a healthy culture that allows for failure is the greatest boon to the product development process: ultimately, finding out errors that have to be avoided will also lead to improvements in machines.

5. Active Co-Creation

Cross-company cooperation has a lot of potential for developing tailor-made solutions that suit all parties involved.

Challenges of Active Co-Creation

- Finding Courage to Open Up:

Years of Silo Mentality and a one-track innovation culture stuck within the narrow boundaries of their own organization can make it difficult for traditionally structured industrial companies to take the step into partnership-based cooperation. - IT-Security und Industrial Espionage:

In a survey of 5,000 IT managers internationally, 51% of respondents reported being hit by a cyber attack in the past year (The State of Ransomware 2020). With every second company having been the victim of a ransomware attack, fears with regard to data-supported cooperative forms of work, such as costly data encryption (Ransomware), irreparable loss of image and corporate espionage are understandably rising.

Solutions for a cooperative Partnership:

- Work Closely with the Customer:

better you understand the customer's requirements and expectations, the more precisely you can develop solutions and associated components. - Cooperate with Established Partners:

Active co-creation is a question of trust: both sides have to open up, enter into an exchange and ensure a high degree of transparency. Companies that have been on the market for years have already made a name for themselves, are usually stable enough and have enough experience to enable equal, dependable cooperation.

Conclusion: Important Innovation Topics in Mechanical Engineering

Years ago, it was predicted that no other industry would invest as much in innovation as mechanical and plant engineering. Today, experts see a lot of as-of-yet untapped potential for the sector, and they’re calling on the industrial sector to be open and courageous in their search for new ways to master the challenges of the future. Cooperation with competent and experienced partners from the ground up is playing an increasingly important role at all levels.

Would you like to learn more about Roll Forming in order to develop innovative and sustainable products? Then simply download our process map and feel free to contact us for an informative, productive chat.

Read more

Similar articles

Is Steel the new Aluminum? Comparing 2 strong Materials

Is Steel the right Choice for you? Here's what Designers & Product Developers need to know