Steel doesn’t grow on Trees? How to deal with Raw Material Scarcity

The shortage of raw materials due to international and local crises in the past months has once again shown us how much we depend on valuable resources. Without these raw materials productions come to a standstill, deliveries are delayed, costs skyrocket, revenues dwindle and, in the worst case, individual components have to be completely redesigned and manufactured from alternate materials.

Yet, dealing with this currently significantly noticeable scarcity of raw materials is not a sudden problem, and the perceived dependency is not one-sided. Every company can make a significant structural and organizational contribution to a reliable availability and procurement of materials. Using steel as an example, I would like to explain to you how this can be achieved, and which experiences Welser Profile have gained in this respect.

When Raw Materials become scarce

The HWWI commodity price index monitors and evaluates the price developments of various commodities, including energy and metals, in order to record trends and fluctuations on the international commodity markets. It shows that the global shortage of raw materials and rising prices are due to increased demand and limited availability. This is partly due to the rising demand for commodities in emerging countries, which have a greater need for resources due to their economic growth.

The COVID-19 health crisis has also exacerbated the shortage of raw materials due to lockdowns and production stoppages in many parts of the world. Another significant factor is the war in Ukraine, which has led to supply chain disruptions in global commodity trading and thus to price fluctuations and shortages. The combination of these factors has had an impact on various sectors of the economy. The steel industry, which sources metals such as iron and nickel from Ukraine and natural gas from Russia, was also affected.

The price of steel as a raw material also experienced a rollercoaster ride between 2020 and 2023. While the price of a tonne of unalloyed construction steel (E295) was still around EUR 500 in September '20, it skyrocketed to up to EUR 1900 in '21 and '22. The resulting shortage of raw materials led to the diversion of familiar supply chains in logistics, tense situations due to the availability of freight space and effects on production capacity in many industrial companies. In 2023, the price of construction steel gradually fell again and settled at around EUR 1,000 per tonne. Mind you, this was still twice as high as before the crisis years.

Steel as a Raw Material – scarce or available?

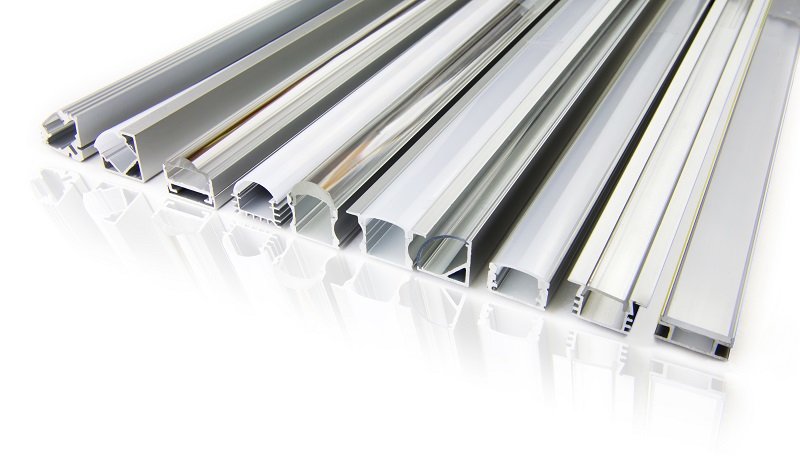

Justifiably many organizations currently ask themselves, which materials they should bet on and how sustainable handling of the respective raw materials can be ensured. Our customers, for example, are constantly asking the question: aluminum or steel? And if steel, how scarce or available is this material?

Basically, the availability of crude steel in Europe is sufficient. However, in view of the existence of more than 2,500 different types of steel, this question must be answered on a case-by-case basis, or a suitable and available steel selected for the project in question.

- As of lately, the shortage of raw materials of the actually available steels can be influenced by quite different factors, such as

- High demand for certain steels, for example to use CO2 reduced materials to achieve set climate targets

- Increase in tariffs or penalties, because of political developments

- Removal of an important market component, e.g. due to the replacement of a blast furnace

- Force majeure, due to climate-related disasters such as floods or extreme cold periods

- Sudden activities of competitors, both from the local environment and from international markets, such as China or India

5 practical Tips for dealing with Raw Material Shortages

As a long-time processor of steel products, we are familiar with unexpected market developments that repeatedly lead to a shortage of raw materials. On the one hand, we are affected by them ourselves; on the other hand, we support our customers in dealing competently with fluctuating material availability. In the last 25 years, we have gained a lot of experience, made one or two mistakes, but above all we have learned numerous valuable lessons. I would therefore like to share with you the 5 most important practical tips for dealing with raw material shortages:

#1: Focus on Raw Materials that will be available in the Future

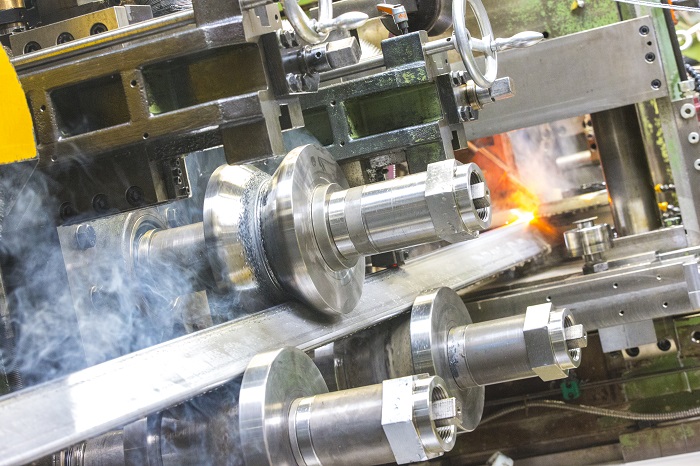

Complex market developments are difficult to predict over the course of many years. However, we at Welser Profile know that as for the production of rolled steel profiles, our production process is based on a raw material that will continue to be highly available in many variations in the future.

So, instead of choosing today’s cheapest alternative for your components, production plants, etc., include the estimated future availability of materials and raw materials in your decision making. After all, market developments such as those in recent months can quickly turn the tide.

#2: Buy local

Calls for localism are becoming louder and louder in numerous industries. At Welser Profile, we have always been committed to a “buy local” principle. Reducing supply chains as well as supporting future-oriented activities of the local steel industry towards Green Steel have ever since been convincing advantages for us.

By focusing on regional market supplies, you build on good relationships with local markets and benefit from fast and direct supply routes, even when raw materials become scarce globally.

#3: Assess your Needs holistically

One of our most important lessons learned is that we assess demand holistically based on a wide range of different perspectives. In a trusting exchange with our partners, we develop scenarios and strategies to ensure that supply is possible even in the event of a problem such as raw material shortage.

Adopt a holistic view of your demands and enter in transparent exchange with your own suppliers and partners. The broader your perspective on potential shortages, the better you can anticipate your needs and ensure supply.

#4: Think process-integrated when finding Solutions

We repeatedly notice in roll forming that raw material shortages can not only be prevented externally, but also internally. This is because producing roll-formed steel components can integrate many more functions in a single production step than in alternative processes. For example, extruding aluminum keeps entailing more process steps for active function integration, more material, and more scrap.

Material availability can therefore also be partly determined by process-integrated solutions, because calculated on larger volumes, even small savings in a component have a large effect on the required material and scrap quantities.

#5: Maintain good Partnerships

We emphasize on maintaining great relationships with our suppliers and partners. For example, we jointly drive the transformation to CO2-neutral steel production and support our partners in consolidating a strong local steel industry in Europa.

Cultivate good partnerships because they always pay off in the long term. Loyalty and mutual support come into their own, especially in times of crises.

Conclusion: A sustainable Management of Raw Material Shortages pays off

Steel does not grow on trees. But it is a raw material that can be planned for – provided a local acquisition, a holistic demand analysis and a process-integrated solution finding. This sustainable approach also pays off in the long term for other scarce raw materials such as crude oil, wood, or synthetic material. Don’t let your business activities be determined by raw material shortages. Instead, set the course yourself to ensure a reliable supply of materials in the best possible way and independent of external influences.

Time to go new ways? Let's talk to each other!

Read more

Similar articles

Photovoltaics: Green Steel for Green Energy

Is Steel the right Choice for you? Here's what Designers & Product Developers need to know